Production has been stopped!

Only a small number of pieces left in stock.

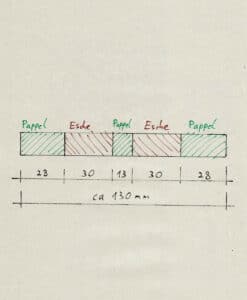

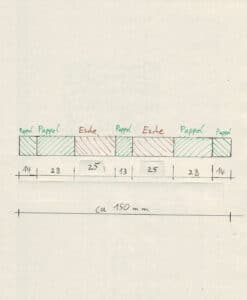

bCore 200 – light balsa wood 190 cm long, 12.1 cm wite, 1.4 cm thick size M

Middle part 55 mm balsa wood, laterally 33 mm albasia wood.

This is the new Core from bComp. The bCore D200 is no longer manufactured.

weight ca. 800 g ( +/- about 80 g )

Manufacturer:

bCores® 200 is a structural core suitable for composite applications. The core is made of Balsa Plywood reinforcement materials to significantly improve mechanical properties, especially fatigue and long-term shear properties in length direction.

The balsa plywood ensures an exceptionally high compression strength and stiffness, which guarantees good bending properties of the core.

bCores® is the lightest wood core on the market.

Low density flat balsa wood veneers is combined to obtain a high-performance lightweight core with excellent shear and fatigue properties and provide typical “woody” feeling. Bcomp developed the core material specifically for skis but it also perfectly fits water sport industry.

The bCores are compatible with standard resins, epoxies being ideal.

All tests have shown exceptional core-face ad-hesion results, which is further increased thanks to the shear webs.

How to calculate the right core thickness?

The bCores have a lower flexural stiffness than classical wood core.

Therefore the bCore has to be slightly thicker in order to reach the same flex stiffness as with a standard wood core.

For calculating the right thickness of the 200 you can use following core bending stiffness: 2200 MPa. Bcomp provides a tool for thickness calculation on their website. I have it also available.

The core thickness can be calculated compared to a conventional ash core ski with the same fibre layup.

Just sent the thickness and the width of the corresponding ash core and your fibre layup.

I’ll try to write a manual for the tool a plan to provide both on skibaumarkt.de, the tool and the manual.

Processing tips:

The surface of the cores is quite porous. Thus, to minimize weight, the amount of resin used to glue the face has to be controlled.

Typically, count on 100-150 g/m2 resin for core-to-skin bonding. Additional resin will not improve the core-skin bonding.

Apply the resin just to the fibres and not directly to the core.

The core can be planed but it’s a bit sensitive. Just use very sharp blades and leave the core longer when planing.

Due to the vertical flax layer orientation the cores become a lot stiffer than you’ll expect before lamination. The flax bonds to the upper and lower fibre layer during lamination building strong torsion boxes.

Those skis we build with flax are very light and behave really well.

Tips for processing and assembly of the binding you’ll find here and here.

Within my “tipps” you’ll find two pictures showing how

to design the binding area. When not realizing it

tapered this will result in a predetermined breaking

point of your skis.

data sheet

Price per piece

Related products

25,00 €

0,75 €

4,50 €

13,00 €

23,00 €

0,75 €

8,00 €

27,50 €

27,00 €

5,00 €

28,00 €

21,50 €

Deutsch

Deutsch